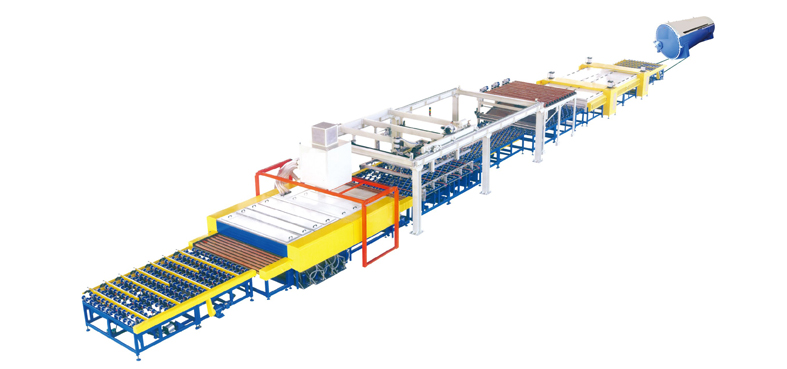

PVB System with Autoclave for Laminated Production Line

Direction of production line starts from left and continues to right.

Production line equipment:

1. Horizontal Glass Washing Machine for Low-e

2. Automatic Glass Transfer Tables 2 sets

3. Connecting Table and PVB Placement

4. Electrical PVB Stock Unit

5. Infrared Flat Rolled Press Machine

6. Infrared Convection Autoclaving Machine 2500x3500 mm

Horizontal Glass Washing Machine Working speed of the line depends on thickness and dimension of the glass. Increase of thickness and dimension of the glass working speed will be slow. Horizontal washing machine is all stainless and can wash Low-e glass. Thismachine is special equipment It consists of loading section,washing section,unloading section,drying section,water detergent systemand blower system. For details, please see technical properties in page for Horizontal Washing Machine.

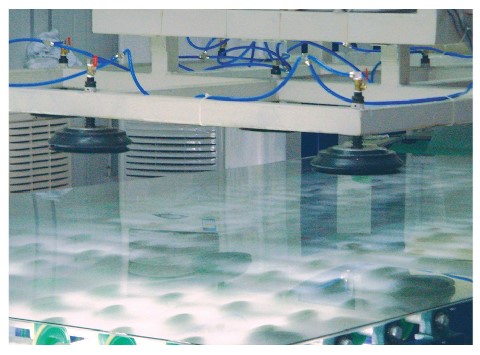

Automatic Glass Transfer Table and PVB Connection

The Machine set is a corollary equipment of laminated glass line,can greatly lessen operator’s labour intensity during mass production.

This set of equipment includes:

1. Automatic laminator

2. Motorized PVB film rack

3. Transfer station

Technical Characteristics

Install rotary wheel table lifting system in the positioning section for comminating small glass.

Combining section can pull the width automatically.

PVB to be separated by the plastic film during operation.

Sucker lifting system is aluminium alloy material.

Rotary wheel lifting mechanism for small glass

Technical Propertiesfor Automatic Glass Transfer Table and PVB Connection

Min. Processable Glass Size 420x350 mm

Max. Processable Glass Size 2500x5000 mm

Working Speed 0.25-5 m/min.

Working Speed of sucker system 4 m/min.

Air Pressure 4-6 Bar

Lifting Height 400 mm

Max. Sucking Weight 800 kg

Number of films can be placed 3 Rolls

Power 0.37 kW

Weight 4000 kg

Infrared Roll Press Machine (Oven)

This is a specialized machine for pre-press and pre-heating of the combinedglass. To squeeze the air from the film between the glasses and make the glass bounded together preliminarily.

This machine consists of loading section-heating section,up-pressing section, heatingsection, down-pressing section, unloading section and electric controlling cabinet.

The heating section is a closed stainless-steel case. There are far infrared mid-wave heaters. The pressing section consists of two pairs of big pressing roller that lie at the both ends of the heating section to squeeze out the air between the glasses. The distance between the rollers is adjustable according to the depth of the glass. There are two areas in heating section. Digital displayed apparatus can control the temperature automatically. The machine has PLC with touch display and single button start,adjust the pressureaccording to the glass thickness and dimension. The conveying speed can be changed by frequency control.

PLC common control heating,transmission and so on and indicate various parameters.

Here’s two areas of the heating section ,the total height is 4.6m,each section is 2.3m. there are 60 infrared heating elements and stainless steel reflector panel,heating room is covered with Silicon cotton and protect by galvanized iron sheets.

The outer cover is cold plate painting.

The promotion structure is made of screw,linear shaft,angular tooth,electrical cylinder

Technical Properties for Infrared Roll Press Machine (Oven)

Min. Processable Glass Size 800x1200 mm

Max. Processable Glass Size 2500x5000 mm

Thickness of Processed Glass 4-80 mm

Air Pressure 4-10 Bar

Working Temperature 180-200 ℃

Working Speed 0.5-4 m/min.

Diameter of Conveying Roller 70 mm

Space Between Roller 200 mm

Power 63 kW

Weight 5000 kg

Length 11000 mm

Width 3600 mm

Height 1500 mm

Infrared Convection Autoclave Oven

Autoclave is a specialized machine for production of laminated,anti-bullet and anti-bombing glass.This machine will melt the PVBfilm and combined two layers or more than two layers glass by high temperature and high pressure. It consists of autoclave body, autoclave door, circulatory blower, heater,cooling system,electric cabinet etc.

The glass after vacuum exhaustion and pre-heating &pre-pressing will be put into autoclave to heat, press and stabilize in order to make glass and PVB film stick .It adopts PLC and touch screen control system which has excess temperature and pressure alarm function ensure safety. Door is opening pneumatically.

Technical PropertiesInfrared Convection Autoclave Oven

Max. Processable Glass size 2440x5000 mm

Shall Inside Diameter 2850 mm

Air Pressure 12.5 Bar

Safe Valve Opening Pressure 14 Bar

Working Temperature 130 ℃

Inside Rail 900 mm

Working Cycle of Autoclave 3.5-4 h

Inside Insulation 80 mm

Pressure Testing Point 1 pcs

Temperature Testing Point 3

Total Power 152 kW

Weight 18000 kg

Length 7800 mm

Width 3600 mm

Height 3500 mm

- Min. Glass Dimension - 420x350 mm

- Max. Glass Dimension - 2500x3500 mm

- Glass Thickness - 4-65 mm

TURKISH

TURKISH MACEDONIAN

MACEDONIAN SERBIAN

SERBIAN ALBANIAN

ALBANIAN RUSSIAN

RUSSIAN SPANISH

SPANISH ARABIC

ARABIC FRENCH

FRENCH GERMAN

GERMAN