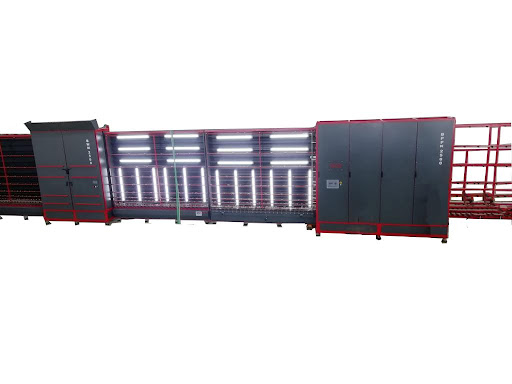

Pneumatic Panel Press Line

Surfaces which contacts directly with water are made of A304 stainless steel

Outer parts of the machine where there is no contact with water is HRP quality steel

300 litre capacity stainless steel water tank

Specially designed water tank discharge and overflow system

Staple type, vibration free brushes for ɛ =0.10 quality Low-E glasses

For each conveyor separate motor

Chain transfer system in conveyor systems

Emergency stop button on each conveyor

Special design for bearing system

Bearing housings aluminium

Special design for conveyor wheels to move heavy glasses

Wiper rubbers and brushes between the section in the washing unit

EPDM and polyurethane conveyor discs, transparent acrylic inner cover

Stepless adjustable feed in washing section

Standard for 2500 mm height and 6 brushes machine each brush has separate motor, othermachines with 2 motors (for other dimensions optional for each brush motor)

On panel press lines 6 balanced brushes are offered as standard in the washing unit.

Low-e glass washing

Washing and rinsing with thermostat controlled hot water

Brush shafts are balanced against vibration

Brush and executive bearing system that does not require lubrication

Rinsing unit

Drying unit with noise isolation and fan cabinet with heat control

Conveyor system without touching to side carrier wheels at drying section

Adjustable speed control

Ability of drying without touching the glass

Washing with hot water and drying with hot air

Automatic water adding with float-valve system

Water compartments corresponding to each washing division in the water tank

Inlet filters for water pumps

Water level control with magnetic safety sensors

Temperature controlled stainless water tank

Low energy consumption

User friendly control panel

By-pass button for washing glasses with big sizes

Possibility to work from left to right or from right to left

Ability to make triple and structural glass

Glass thickness precision and high pressing speed with motion on 3 axes driven by independent automatic servo motordriven (glass position reset, bottom and side height adjustment, joining)

Manual operation and control of all functions

Ability to rank from 100mm to 120mm from bottom

Automatic pressure adjustment for different glass sizes

Bottom and side rests with height and depth adjustment on the profile placement shelf

Conveyor system on rear panel air bed

4-point parallel control with precision ball screws

Press force and vacuum step system that can be adjusted automatically according to the glass size

Front panel which can be opened 40 cm for maintenance

Making the passive active with the quality control section button at the exit of the washing unit

Keeping the glass inside the press stable when the electricity is cut or emergency stop is pressed

Pneumatic pressing section

Press output tilts table

Abrasion resistant consumable material

Electrostatic powder coating systems against corrosion

Using of well-known quality brand system in electricity (Siemens, Schneider, Lenze, Omron) it is compliant with general safety rules

OPTIONS:

- Prewashing Unit

- Open Top

- Valve system for energy saving when there is no glass in drying unit

- Control with electronic float in water tank

- Flap System in Blower

- Heating Resistance System in Blower

- Front first brush hard and movable

- Washing cabin complete stainless

- Processable Glass Thickness max. 2-50 mm

- Self-supporting executive wheel system according to the thickness of the glass (max 19mm)

- Easy cleaning water nozzle system

- Double speed washing exit conveyor system

- Press outlet with hydraulic tilting table for heavy glasses

- Super spacer application section

- Glass transfer table

- Possibility of making 3300x6000 mm press line

- Automatic Argon gas filling

- Pressing of structural glass

- Processable Glass Thickness - 2-12 mm

- Min. Processable Glass Dimensions - 170x350 mm

- Max. Processable Glass Dimensions -

For 1700 mm Height 1700x6000 mm

For 2000 mm Height 2000x6000 mm

For 2250 mm Height 2250x6000 mm

For 2500 mm Height 2500x6000 mm - Min. Pressable Glass Dimensions - 170x350 mm

- Maks. Pressable Glass Dimensions -

For 1700 mm Height 1700x2750 mm

For 2000 mm Height 2000x2750 mm

For 2250 mm Height 2250x2750 mm

For 2500 mm Height 2500x2750 mm - Washing speed - 1-15 m/min

- Width - 2000 mm

- Lenght - 18000 mm

- Height -

For 1700 mm 2700 mm

For 2000 mm 3000 mm

For 2250 mm 3150 mm

For 2500 mm 3400 mm

- Weight - 2500-3500 kg (Depending on Height)

- Voltage - 380 V

- Frequency - 50-60 Hz

- Total Power -

1700 mm 20 kW Structural Glass Option 25 kW

2000 mm 22 kW Structural Glass Option 27 kW

2250 mm 26 kW Structural Glass Option 31 kW

2500 mm 28 kWStructural Glass Option 33 kW - Air Pressure - 6 Bar

- Air Consumption - 150 L/min

TURKISH

TURKISH MACEDONIAN

MACEDONIAN SERBIAN

SERBIAN ALBANIAN

ALBANIAN RUSSIAN

RUSSIAN SPANISH

SPANISH ARABIC

ARABIC FRENCH

FRENCH GERMAN

GERMAN