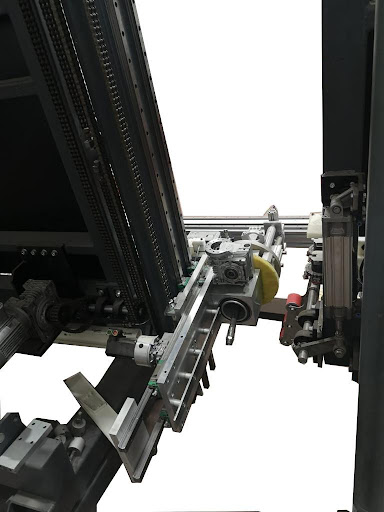

Automatic Sealing Robot

• Material used: polysulfide, polyurethane, glazing silicone, structural silicone

• Automatic unit height detection system

• Auto flow rate change for unexpected sealant depth changes

• Unit holding and synchronized feeding system with vacuum cup

• Conveying system for preventing sticking of sealant to conveyor

• Cleaning system for conveying system to keep system free from sealant

• Auto-flushing system for stand-by cases to keep mixing template safe against solidification

• High pressure solvent application for auto flushing

• CNC drive system fast and accurate positioning

• Increased resistance for high pressure and chemical corrosion in main material pump

• High pressure and flow rate with servo hydraulic system

• Dosage range between 1/5-1/15

• Automatic corner rounding

- Min. Glass Dimensions - 400X400 mm

- Max. Glass Dimensions - 2500X3210 mm

- Glass Thickness - 3-12 mm

- Thermo Glass Thickness - 12-50 mm

- Thiokol Extrusion speed - 5-35 m/min

- Thiokol Extrusion Thickness - 6-24 mm

- Thiokol Extrusion Depth - 2-15 mm

- Conveyor Speed - 0-48 m/min

- Power - 15 KW

- Weight - 3600 Kg

- Sealing depth - <10mm

- Elevation - 400mm (Standard height)

- Air pressure - 6-8 bar

TURKISH

TURKISH MACEDONIAN

MACEDONIAN SERBIAN

SERBIAN ALBANIAN

ALBANIAN RUSSIAN

RUSSIAN SPANISH

SPANISH ARABIC

ARABIC FRENCH

FRENCH GERMAN

GERMAN